Assignment 3 R-Submission

I have expanded on the Analysis of the Control Charts

The changes are in Red.

Introduction and Objective

Singh Inc. in conjunction with Goff’s Enterprises is developing a new re-usable window insulator kit based on the Goff’s existing technology of Climate Curtains. The product will be made from completely recycled materials consisting of 100% recycled vinyl and insulation material. The insulation material will be a combination of recycled paper and recycled fiber glass. This will help to give the new green product a lower Life Cycle Assessment (LCA) number which means lowering the embodied energy needed to produce the new product. The recycled insulation product will be converted and mixed into a liquid form so that they can be easily injected using existing pulping technology utilized by the building product industry. Turing the insulation into a liquid form and injecting it into the new window kits makes the process highly efficient because it can be completely automated using robotic arms and injection nozzles. This new process of making the insulation will be a joint venture between Singh Inc. and Goff’s Enterprises eliminating their need to purchase insulation from a third party. This will help reduce product cost and make them more environmentally friendly.

For this assignment we will be utilizing Statistical control charts to analyze the process of making the insulation slurry and injecting into the newly formed vinyl layer that make up the window insulation kits. We will be using the process control method to see what kind of variations we are getting the product and if the process is in control or out of control. Also we will be analyzing any non-conformities encountered thought the production cycle.

Brief Description of Methodologies Applied

Statistical Control Charts

In order to complete this assignment 2 different types of statistical control methods will be utilized the Variable control charts and the Attributes control charts.

Two types of charts within a variable chart are R and X-bar chart. The R chart provides information about the variability within the standard deviation of a sample of "N" units. Whereas the X-bar chart shows the mean value of the quality characteristics over several samples. Variable charts are used to measure control processes whose characteristics are continuous variables such as weights and length. Figure 1 below shows the equations for the X-bar and R charts.

Figure 1

In an attribute analysis, three types of charts that are used, the P, C and U chart. The P chart focuses on the nonconforming as a function as a percentage or fraction. The U chart analyzes the number of nonconformance per unit. The C chart is a control chart for the number of defects or nonconformities. Because attribute control charts deal with characteristics that are hard to measure numerically, it is given either a pass/ fail rating. Figure 2 below shows the equations for a P chart. The centerline, upper and lower control limits will be calculated for both the variable and attribute charts. The centerline is a statistical average of the data and is located in the center of the control chart. Whereas the upper and lower control limits are calculated using ± 3 standard deviations.

Figure 2

As you can see from the Charts the process is in control. There are no points above the Upper Control Limit and no points below the Lower Control Limit. There are no consecutive runs of 7 points or more above or below the mean value Bar or the center line calculated from the data. The Data can be found in the Appendix.

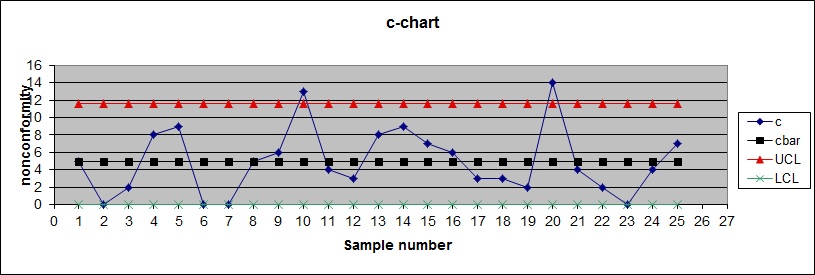

Next we will be utilizing the Attributes charts to analyze parts of the quality process that cannot be quantified or is too hard and too expensive to quantify. This when the attributes control charts are used. Using the P-Chart and C-Chart we will be analyzing the mounting and sealing system of the window insulation kit. This is the mounting brackets for the windows and the Velcro sealing system to create the airtight seal. Using the C-Chart we analyzed 25 samples of 100 runs each of the re-usable sealing kits. The resulting data was compiled and a C-chart was made seen below.

As we can see the process is out of control and the points that are above the control limits seem to be occurring at every 10th sample. In order to figure out why the process is out of control a Quality Assurance Investigation Team was assembled the process was analyzed. After inspecting, the tools specifically the applicator that applies the special adhesive that attaches the Velcro strip to the widow frame. There are of applicators working at any given moment and they switch every ten batches. As it turns out there was a blockage in one of the adhesive supply line, which led to an inadequate amount of adhesive being applied. This is the reason why the sealing strips were failing. The applicator was fixed -and the failed batches were recycled. As you can see from the new C-Chart below the process is back In-Control.

Next we used the U-chart to analyze the non-conformities in the product when the sample size varied from batch to batch. We were producing in different numbers In order to minimize Goods In Process (GIP) so we can minimizes cost associated with it. This helps improve the profit margin and helps us stay competitive. This strategy is in keeping with the JIT manufacturing. The U-Chart is illustrated below.

As you can see the process is in control, there are no points above the UCL or below The LCL. Nor are there any 7 consecutive points above or below the center line.

Analysis

Both the X-Bar chart and The R-Chart show the process is in control. There are no points above the Upper Control Limit and no points below the Lower Control Limit. There are no consecutive runs of 7 points or more above or below the mean value Bar or the center line calculated from the data. This shows that the variation of the insulating factor R of the Kits is within spec and there is no need for alarm. If the control chart had points above or below the UCL or LCL than an investigation would have been necessary to figure out what was happening and what was causing the process to be out of control. The Data can be found in the Appendix.

The C-Chart was initially out of control because of tooling malfunction. There were points above the control limits and they seem to be occurring at every 10th sample. In order to figure out why the process is out of control a Quality Assurance Investigation Team was assembled the process was analyzed. After inspecting, the tools specifically the applicator that applies the special adhesive that attaches the Velcro strip to the widow frame. There are 2 applicators working at any given moment and they switch every ten batches. As it turns out there was a blockage in one of the adhesive supply lines, which led to an inadequate amount of adhesive being applied. This is the reason why the sealing strips were failing. The applicator was fixed -and the failed batches were recycled. As you can see from the new C-Chart below the process is back In-Control.

The process was brought back into control by rejecting the units produced by the malfunctioning tool and doing the control chart again. After the blockage from the supply line was cleared the C-Chart was back in control for the next test samples.

The U-Chart was utilized for analyzing the non-conformities when we were producing in different numbers from batch to batch. The U-Chart was used to analyze the attributes of the mounting system for the Window Insulator Kit. Due to the demand and work stoppages from day to day the U-Chart was used because the sample sizes varied from batch to batch. It was found that the mounting systems were in control because there were no point above the UCL or below the LCL and there were no 7 consecutive points above or below the center line.

Collaboration

Goff's Enterprises - We are collaborating with them on a joint venture to produce insulation for the Window Insulator kits in house from 100% Recycled materials.

Lenze - We are using there smart energy efficient space saving motors gear drives to fully automate the production process.

Interlake - We will be using there fully automated warehousing solutions to maximize warehousing space and eliminate unnecessary labor costs. Since the entire process from warehousing to shipping will be automated using robotic lift trucks it will be much safer free from human error.

Datex - We will be using the 3PL supply chain software and hardware to make the ordering, selling, and shipping process streamlined. They supply chain software will also enable us to utilize the JIT manufacturing process to eliminate unnecessary inventory and maximize profits.

Summary

We used the control charts to analyze the different process for producing the Window Insulator kits. the R-Chart and X-bar charts were used to analyze the variable process of injecting the insulation in the vinyl sleeve. The C-Chart was utilized to analyze the non-conformtites in the Velcro mounting and sealing hardware. Lastly the U-Chart was used to inspect the non-conformities when the sample size varied due to production numbers changing from batch to batch.

Further Work Needed

We should be using these control charts to analyze the process on a regular basis. Put in place a good procedure to record reliable data because the charts are only as good as the data they are based on. Using these great tools we can make incremental changes to make the process more efficient and more profitable.

Appendix

Refrences

http://www.interlakemecalux.com/

http://www.goffscurtainwalls.com/

Ranky, P G: TQM System Modeling e-Textbook: eLearning Pack ID: IE673-Spring2012-95-35

Executive Summary of Discussions

During this week’s discussion we talked about 3D solar cells, China’s Exodus, the power profiler and how clean the energy that you are consuming.

First the 3D solar cells and how they are much more efficient at capturing and utilizing the solar rays that hit the panels. They are much more efficient than the ones in existence today but at the same time very expensive. The 3D solar cells use Carbon Nano tube technology to achieve the 3D structure that makes it possible to capture all the solar energy that hits the panels. Solar power is already the most expensive form of energy production and this isn’t going to help its case. Solar energy needs to get cheaper in order to be viable as major form of energy production. Getting more expensive isn’t going to help.

The power profiler article was very interesting it lets you know just where your energy is coming from. For me personally majority of it came from coal and nuclear power, about 40% each. This was a bit of an eye opener. So I looked into whether I can get power from different more earth friendly sources. Viridian energy offers more green choices in the area. You choose to go completely green or do a mixture of energy sources.

I also posted an article about how much does it cost produce energy coming from different sources. “The lowest per kWh total cost was hydro at $0.03, followed by nuclear and coal at $0.04, wind at $0.08, natural gas at $0.10 and lastly solar at $0.22 and that is only the construction cost, it doesn't even account for the production cost.” As you can see solar is the most costly and that is only construction cost, it doesn’t even include day to day cost of producing and maintenance.

We also talked about china’s exodus from manufacturing. I posted an article about the comparison of European workers and American workers. Study shows American workers are 35% more productive than European, which got me wondering, why are they more efficient. I posted an article explaining the difference and it is because American workers spend more time working than European workers. European workers have a lot more vacation time than their American counterparts. They study only compared how productive the workers based on how much they produced in total. A better measure would be to compare how productive the European workers are compared to their American counterpart over a certain number of hours. The article I posted said the European workers are more productive based on this criterion.

http://njit.mrooms.net/mod/forum/view.php?id=189354

Self Grading

I would give myself a 100% because i have answered every question from the syllabus.